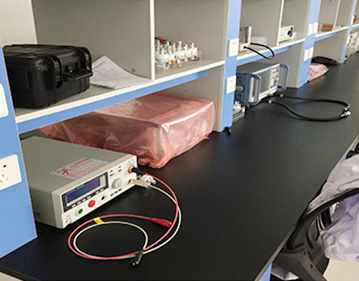

Quality comes from design, Dexin controls the quality by preventing the appearance of abnormal product quality from the source of design.

And the most important thing is only from the source to prevent the occurrence of abnormal quality to achieve the lowest production costs and the required quality.

Since the establishment of our company, Dexin carries out the spirit of "design is the premise, material is the foundation, production is the key, service is the guarantee", actively carry out R&D cooperation with suppliers, and invests exceed 5% of the current year's turnover to develop exclusive raw materials suitable for the company, so that to provide systematic services throughout the life cycle for customers.

Take technological innovation as an inevitable choice for creating value!

Dexin has a high-educated, experienced and innovative technology R&D team; 6 senior engineers graduated from Harbin University of Science and Technology, 4 intermediate engineers, 10 professional and technical staffs. The company pays attention to the recruitment and training for enlarging the R&D team. At the same time, the company provides professional training regularly and arrange staffs to observe and learn from other companies to improve the professional knowledge and innovation capability.

In China, everything develops rapidly, not only people but also buildings. Everyone is searching for a comfortable space where it can live and shelter. With the improvement of living level and the increase demand for electrical equipment, the overloaded operation of lines accelerated the aging and short-circuit of wires. According to the national fire accident statistics from January to August 2018, there are 166,100 fires were reported, resulting in 933 deaths and 560 injures, with a direct property loss of 2,053 billion yuan, of which as high as 34.17% caused by electrical accidents. It is particularly important to protect the buildings and ensure to use electricity safely.

The report of the 18th National Congress of the Communist Party of China proposed for the first time to "build" a moderately prosperous society in an all-round way. It has far-reaching significance! Frequent with the country, bravely assume the mission, new responsibilities in the new era, new journey and new action!

The company's technical R&D team actively organizes meetings to investigate and analyze the reasons as follows:

①Increase in electrical equipment and overloaded operation of conductors;

With the improvement of living level and the increase demand for electrical equipment, causing the current to break through the wire and a short circuit, damage the power supply and cause a fire!

②High temperature resistance defects of insulation

Most of the insulation use the renewable materials. With the increase of electrical appliance ,the wires are overheated,which accelerates the aging of the insulation and causes a short circuit and a fire.

③Natural aging of insulation;

The operating time of the current insulation is about 20 years. The wires are concealed and difficult to replace. Due to the complex operating environment, once the surface of insulation is aging, it will corrode and permeate the insulation layer rapidly, causing in short circuit and a fire.

④Potential safety hazards in the construction process;

The rough construction during the wiring process caused the insulation layer to be scratched and damaged. The scratched part is equivalent to the insulation thickness is not up to the standard. The insulation greatly reduces the resistivity to be withstand during the electrical process, which is easy to cause breakdown and leakage cause a fire.

注解:

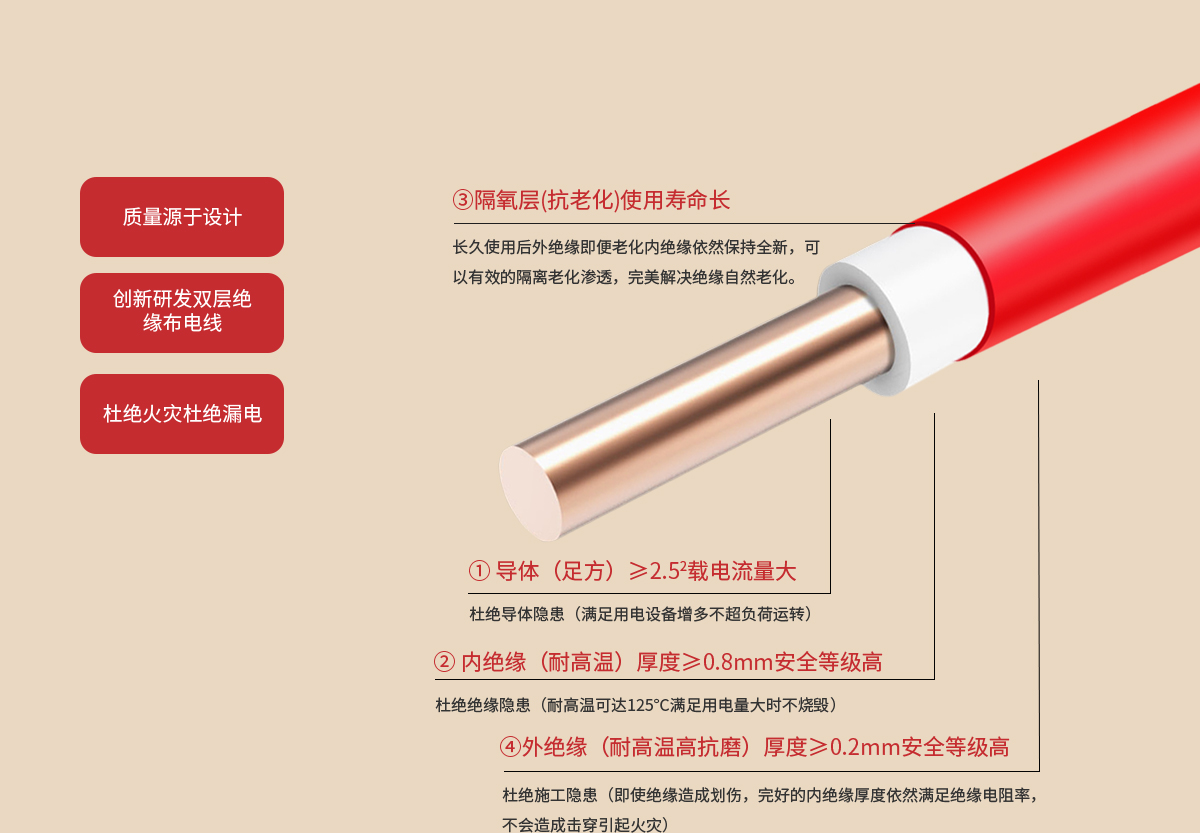

①无氧铜(T1)含铜量99.97%,以2.5平方布电线为例:直径≥1.78;截面积≥2.5²mm,载电流量大(满足家庭用电设备增多)。

②优质聚氯乙烯绝缘料,阻燃内绝缘耐高温90℃,绝缘厚度≥0.8mm,360°绝缘均匀;(耐高温;使用寿命长,杜绝击穿)。

③隔氧层:隔离保护内绝缘,阻断老化渗透,长久使用外绝缘老化后,隔氧层可以有效的保护内绝缘老化渗透,保持全新,完美解决绝缘自然老化,真正与建筑同寿命,70年房子不拆70年电线不换。

④优质聚氯乙烯绝缘料,阻燃外绝缘耐高温90℃,高抗摩,绝缘厚度≥0.2mm,解决施工过程中的安全隐患,即便野蛮施工对绝缘造成划伤,内部绝缘的厚度也足够满足绝缘电阻率,不会造成击穿短路。

PROCESS INTRODUCTION

Process Introduction

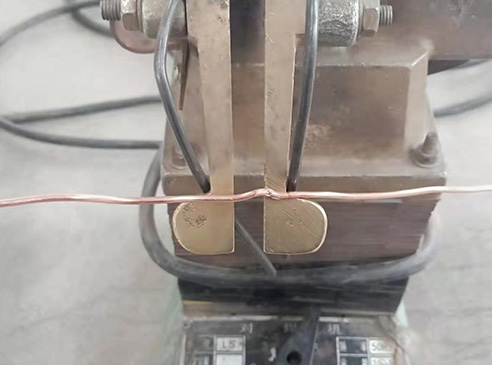

原电焊对接工艺

现引进冷接工艺

Butt welding process defects ①

The original conductor butt joint is oxidized, and the resistance increases. The cold welding joint part has no oxidation and the original conductor current carrying capacity will not increase the resistance.

Butt welding process defects ②

The electric welding butt joint makes the original conductor joints uneven, easy to cause insulation eccentricity. But the cold welding process joint is smooth and flat.

Tensile strength:

There is no defect in the tensile strength of the electric welding butt joint process or the cold joint process, both are more than the original conductor.